When a rubber part breaks at the wrong time, it can do a lot of harm. A little gasket leaking on an offshore platform, a hose breaking in the desert heat, or a rubber seal breaking within industrial machinery can all disrupt work, raise costs, and even put people in danger.

Companies use advanced rubber testing for this reason. It is the science that makes sure that all rubber products, no matter how big or tiny, work exactly as they should, even when the weather is bad.

We’ll explain what advanced rubber testing is, why it’s important, how it makes your products live longer, and how labs like Falcon Lab ensure rubber parts can handle intense heat, chemicals, pressure, and regular use in this post.

Let’s make it easy to understand and use.

Rubber is robust, flexible, and utilized a lot, yet it may also be affected by its surroundings. Rubber can start to break down when it is utilized outside, in factories, or in very hot or cold weather.

Here are some things that hostile conditions can do:

All of this affects performance, safety, and lifespan. That’s why advanced Testing is so important; it helps you find problems before they happen.

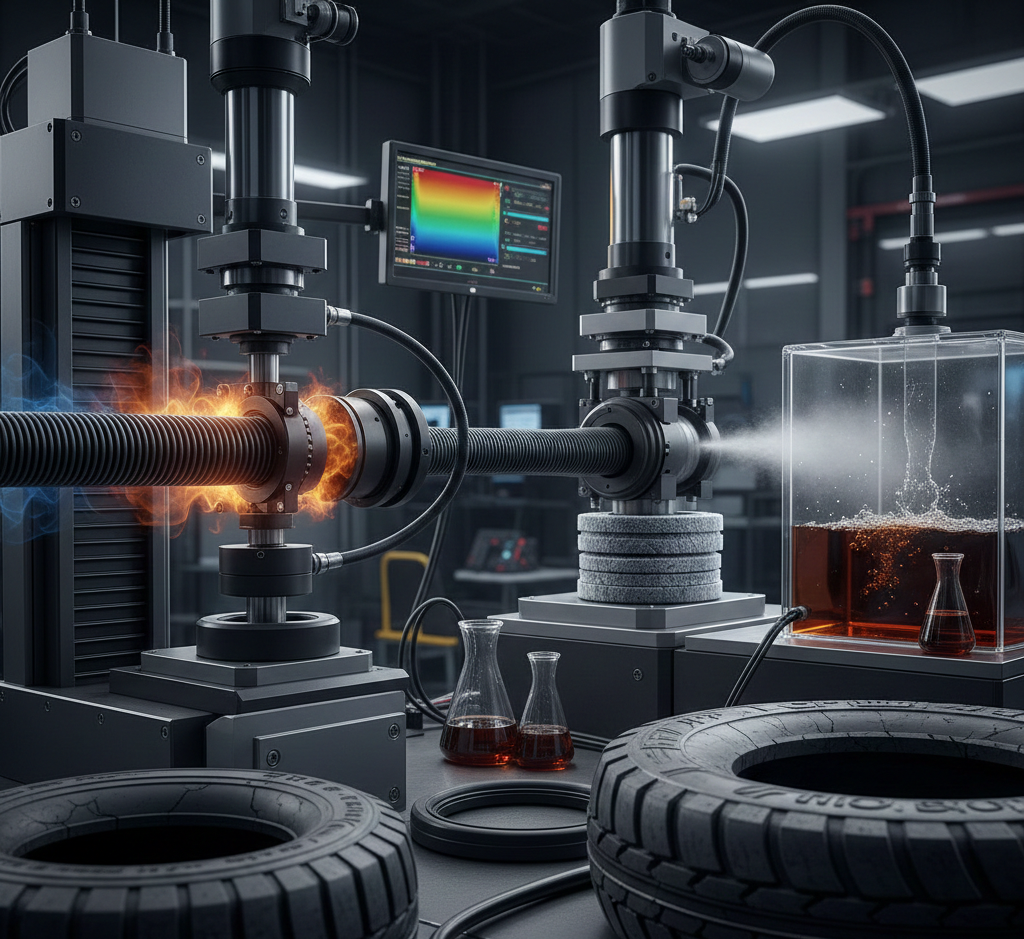

Basic Testing looks at fundamental factors like color or hardness. But advanced Testing goes beyond. It puts the rubber under stress to examine how it performs over time and recreates the same circumstances your product would face in real life.

You may call it a “future simulation” of your product.

Advanced Testing includes:

These tests show you exactly how your rubber product will work in the real world.

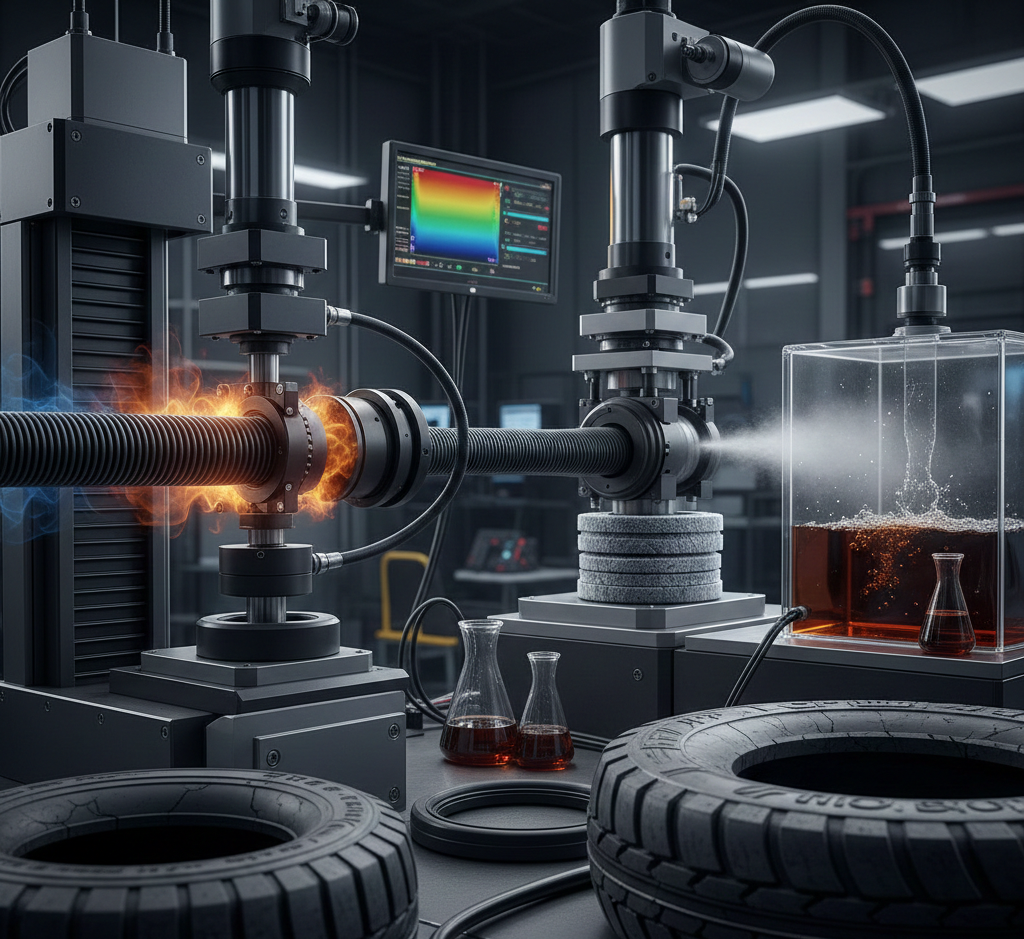

These are several important exams, explained in simple terms:

For days or weeks, the rubber is kept in a hot room. It makes it look like it has aged naturally over years.

Why it matters: It reveals how long the product will last.

The samples are immersed in lubricants, fuels, cleansers, or other substances that the product will come into contact with.

Why it matters: You find out if the rubber will get bigger, softer, harder, or weaker.

Rubber is pressed for hours at very high temperatures.

Why it matters: Tells you if a seal or gasket will keep sealing or start leaking.

The rubber is pulled till it cracks.

Why it matters: It shows how strong it is and when it will break.

Rubbing or scratching the surface over and over.

Why this is important: This is important for pieces that are near sand, dust, or machines that are moving.

Samples are quickly moved from very hot to very cold.

Why this is important: Finds the answer to whether rubber breaks when the temperature changes quickly.

Rubber is bent or stretched many thousands of times.

Why this is important: demonstrates the lifespan of flexible items like tubes or bellows during use.

These tests all give makers a better idea of how their rubber pieces perform in tough conditions.

The real benefit of better Testing is that it helps companies avoid loss, make better products, and choose the right materials from the start.

If a rubber mixture doesn’t pass a chemical test, experts can use materials that are more durable like EPDM, FKM, or NBR.

Testing finds problem areas early, so concerns can be fixed prior to the good is made in large amounts.

3.This renders things more secure and reliable.

Rubber parts that you can trust will stop leaks, broken machines, and unanticipated delays.

It’s much cheaper to test than to break equipment, file warranty claims, or stop production.

The oil and gas, construction, automotive, food processing, and manufacturing businesses all rely on strict rules. Testing checks that everything is up to standard.

Customers believe your product’s performance after it has been tested in a lab.

The lab found after further Testing:

What is the answer? Change to a unique high-temperature rubber composition and a better curing procedure.

What happened?

This is how Testing directly makes things work better, more reliably, and more satisfying for customers.

A excellent lab doesn’t only run tests; it also helps you understand the data and make the proper choices.

Pick a lab that has:

This makes sure that your results are correct, reliable, and helpful.

To achieve the best results, tell:

There are several special problems in our area:

This makes it much more vital to do advanced rubber testing. Products need to be able to handle more than just normal world conditions, or they won’t last.

Testing keeps your brand, your product, and your customers safe.

It’s not merely a technical imperative to test rubber more thoroughly; it’s also a wise business move. It helps companies make items that are safe to use even in harsh environments and last a long time.

Advanced Testing gives you the following, whether you make seals, hoses, gaskets, rubber parts, or industrial parts: