The Importance of Aluminum Testing for Industrial Excellence

Look around you; aluminium is in every structure, in every vehicle, in every jet that carries us around the globe, and even in the tiniest of everyday devices. This material subtly keeps everything in place.

But what most people don’t realize is that aluminium doesn’t get used just because it looks good or feels light. It’s used because it’s proven, tested, verified, and trusted. Behind every aluminum part, there’s a whole process that ensures it’s safe, strong, and ready for real-life challenges.

That process is what we call aluminum testing — and it’s the heart of industrial quality and safety.

Why Aluminium Matters More Than We Think

Aluminium has become a favourite across industries because it’s strong yet lightweight, corrosion-resistant, easy to shape, and recyclable. It helps make vehicles more fuel-efficient, buildings more durable, and designs more sustainable.

But aluminium isn’t perfect. Its properties change based on how it’s made, what it’s mixed with, and how it’s treated. Even a small impurity or invisible crack can affect performance or safety. That’s why testing isn’t just a formality — it’s what makes aluminium trustworthy.

Why Testing Is So Important

Here’s what it really means for industries:

- Safety first: Aluminum is used in places where failure can’t happen — airplanes, bridges, cars. Testing ensures it can handle stress, pressure, and time.

- Consistency matters: Every batch needs to perform the same way. Testing keeps the quality steady.

- Builds trust: Meeting international standards helps companies earn credibility and confidence.

- Saves money: Finding issues early prevents bigger, costlier problems later.

- Encourages innovation: New designs and alloys are only possible when testing proves they can work.

Testing is basically the quality checkpoint that keeps progress safe.

How Aluminium Testing Works

If you’ve ever wondered what happens behind the scenes, aluminum testing is a mix of science, patience, and precision. It’s not just machines doing the work — its experienced people making sure every result makes sense.

Here are the main types of tests:

- Chemical Composition Testing

Every aluminium alloy starts with a mix of elements like magnesium, silicon, or zinc. Testing confirms that the balance is right. Even the smallest variation can change how the metal behaves.

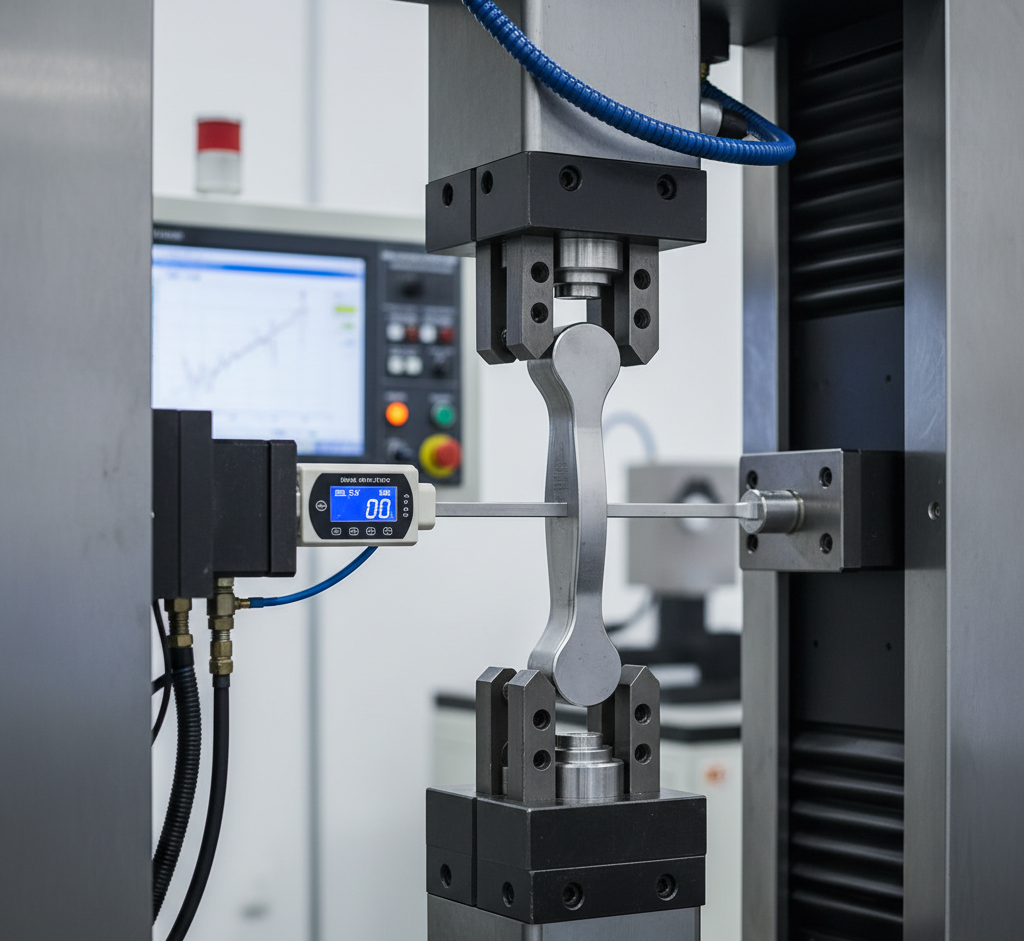

- Mechanical Testing

Here we test the strength of aluminium by stretching, bending, or compressing it to its absolute limits. It is how we determine if it is capable of withstanding repeated stress or huge loads without breaking.

- Microstructural Analysis

Under a microscope, experts study the grain pattern of aluminium. A uniform, fine structure usually means better durability and performance.

- Non-Destructive Testing (NDT)

When it is not possible to physically test a part, non-destructive testing (NDT) techniques such as X-ray, ultrasound, or magnetic tests can be employed to identify any interior defects, similar to a metal health scan.

- Corrosion and Environmental Testing

Even though aluminum is naturally resistant to corrosion testing, these tests check how it holds up in tough environments — from salty sea air to humid, hot climates.

- Dimensional and Physical Tests

Every detail counts. Measurements, density, and surface properties are checked to make sure everything matches the design perfectly.

Industries That Depend on Aluminum Testing

Every industry that relies on aluminium needs testing — but for some, it’s absolutely critical.

Aerospace

Airplanes rely on lightweight materials that can handle extreme pressure, heat, and vibration. Aluminium testing ensures those parts stay strong in the air, where safety can’t be compromised.

Automotive and Electric Vehicles

Testing helps car makers make cars that are safer, lighter, and more efficient. It also makes sure that the aluminium parts in electric vehicles can take both structural and thermal stress.

Construction and Architecture

Buildings and bridges depend on aluminium for strength and longevity. Testing makes sure the material can handle weather, loads, and time without failing.

Marine and Offshore

Metal can be hurtful by saltwater. Testing helps find alloys that can handle tough marine environments and corrosion.

Electronics

From phones to laptops, aluminium is everywhere in electronics. Testing ensures those sleek cases and heat sinks stay durable and safe over time.

It’s About People, Not Just Processes

What really makes aluminium testing powerful isn’t just the machines — it’s the people behind them—the engineers, technicians, and inspectors who understand how every small detail can affect performance.

They’re the ones who notice when something feels off, who read the data not just as numbers but as stories — stories about how a material will behave, where it might fail, and how it can be improved.

That human judgment is what keeps industries safe and quality consistent.

The Challenges

Of course, testing comes with its share of challenges. It takes time, advanced equipment, and skilled professionals. Some companies see it as an added cost, but those who understand the long-term value know it’s worth every penny.

Skipping testing might seem faster, but it can lead to huge problems later — product recalls, safety risks, or damaged reputations. In industries built on trust, there’s no shortcut to doing it right.

Looking Ahead: The Future of Testing

The way we test materials is changing because of technology.

We now have

- AI systems that can tell when something will break before it does.

- 3D imaging that shows flaws deep inside things.

- Automated testing systems that don’t lose accuracy but do save time.

But no matter how much technology we have, testing will always be about people. Technology is capable of measuring, but humans can understand.

Final Thoughts

The next time you look at an airplane, a high-rise building, or even your smartphone, remember that aluminium made it possible — but testing made it reliable.

Aluminium testing doesn’t get much attention, but it’s what ensures the things we build today stay safe and strong for years to come. It’s a quiet part of progress, but without it, modern industry wouldn’t stand as tall.

Because in the end, true excellence isn’t assumed — it’s tested.